TBT mini – product design

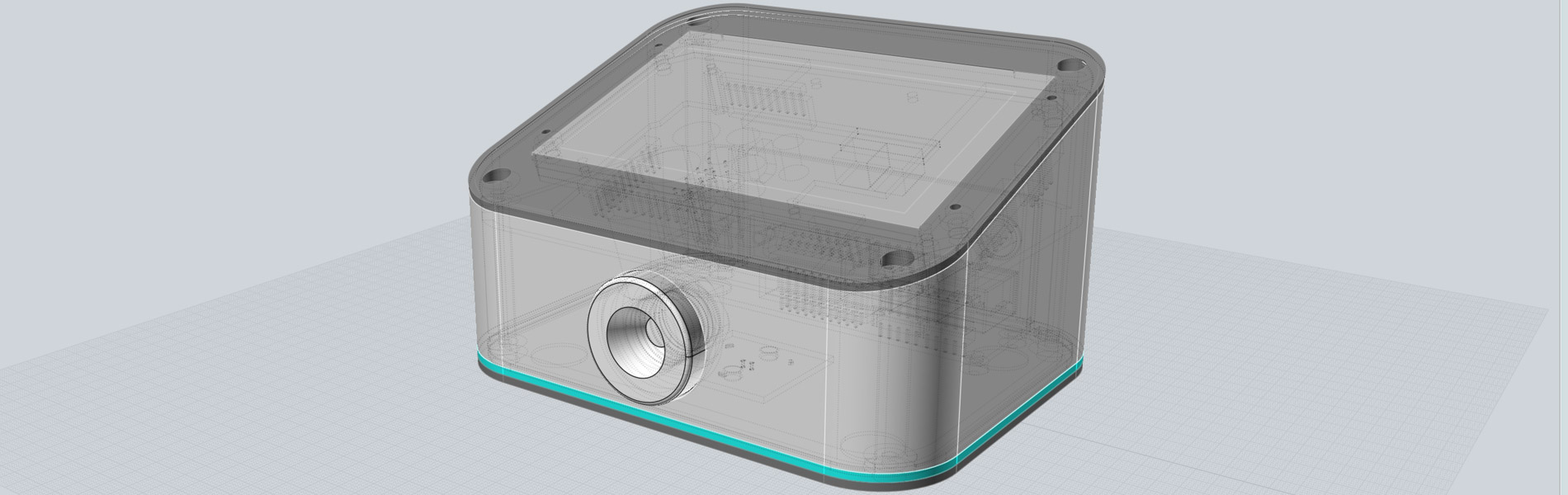

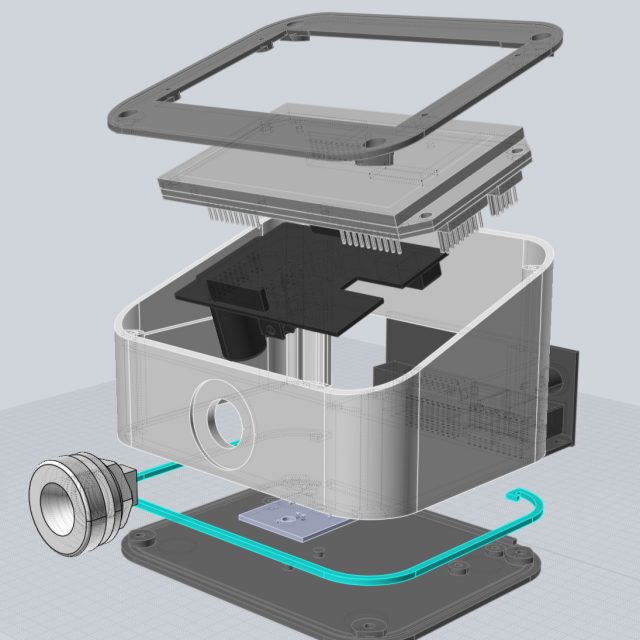

The Austrian electronics company TBT needed a new control device and tasked us with the product design for the now called TBT mini. It needed to fit a 4.3” screen, several circuit boards including components and cables, a lock for service staff, as well as a connector plate. Other key design requirements were relatively straight design, as the case needed to be cast using silicone molds, as well as using two to a maximum of three pieces for it.

This has been a new experience for us, as we did not design products for the purpose of manufacturing yet. We were however up to the task because of our experience in hard-surface-modelling, as well as an educational background in 3D-CAD software. The key difference to 3D modelling for rendering or applications is, that we had to create volumes rather than surfaces. This meant that, apart from the visual design and having enough space for all the components, we also needed to consider structural integrity and assembly components.

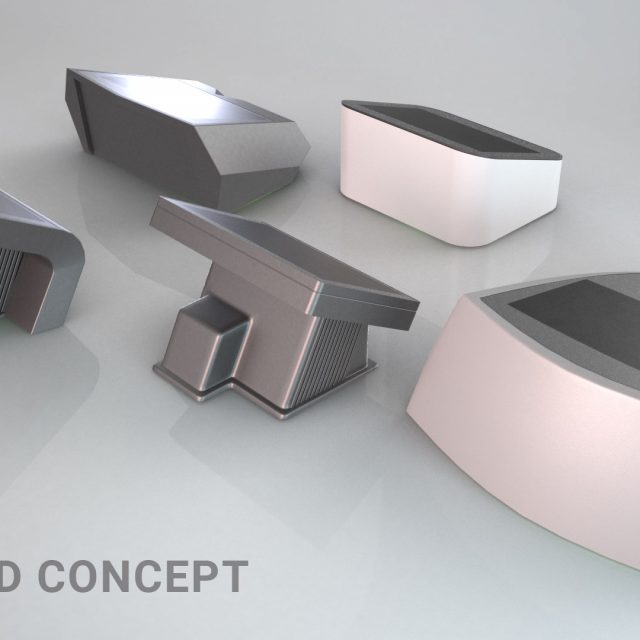

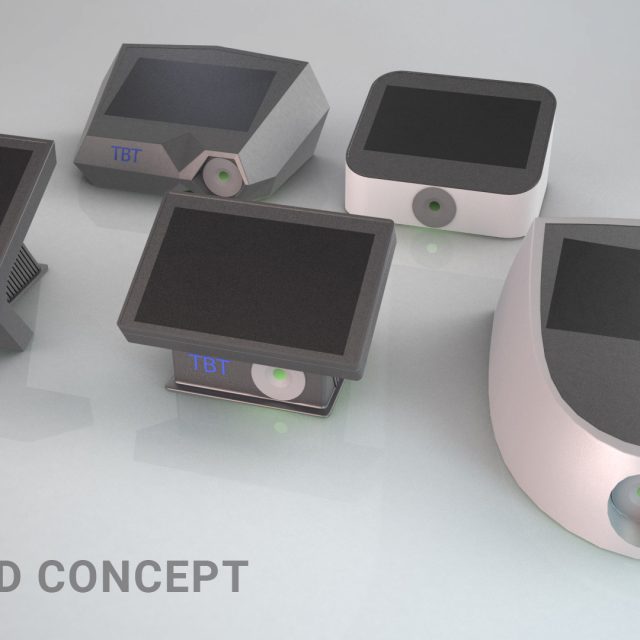

The first phase of this project was the visual design process. We started off by experimenting with many different styles, keeping in mind, that the TBT mini stands on its own and does not need to fit together with other TBT product designs. A variety of design ideas were blocked out using 3D software, two of which were then 3D-printed to create prototypes. After the client voted for the best design, we started with the second phase, the design of the device in a volume modelling software for manufacturing.

The TBT mini has several applications in catering and POS (point of sale), designed to serve as an input panel to communicate with cash registers and controllable devices. It also comes with an optional LED lighting strip at the bottom.

Client: TBT elektronische Systeme